Selecting the right pneumatic valve that can be beneficial to your machine requires 3 important things.

1. Shifting forces

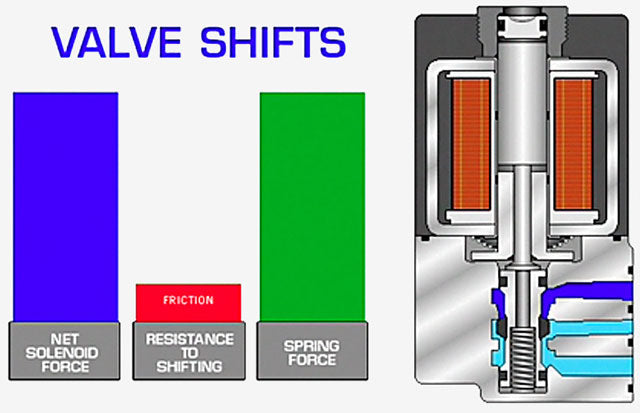

If you want a reliable valve, you need high shifting forces. It’s as simple as that. A valve with higher force will shift through more contamination throughout its life. How can you determine shifting forces? Speed. Simple physics tells us that a higher force results in higher speed. Fast valve = high shifting forces = more reliable valve.

2. Balance

In applications, it is usually critical that the same result happens each time a valve shifts. A filling machine must fill bottles to the same level each time. A glue dispensing gun must place a glue dot in the same place every time. A sorting machine must eject bad parts at the same time each instance. In order to do all this, a valve must have the same shifting force (thus the same speed) at all pressure levels, to compensate for variations in pressure during normal plant operations. This attribute is called utilising a “balanced design” pneumatic valve.

3. Orifice size

No need to go into too much detail here…the bigger the smallest orifice in the valve is, the less likely the valve is to get clogged and not function. Try looking at filter specs to see where manufacturers believe the problems start for their orifice. For instance, a 40 micron spec would indicate a larger orifice than a 5 micron spec. Shifting forces, balance, and orifice size are all important in selecting the right product for you.

Contact a Pneutech Sales Engineer to discuss these factors and for a free product demonstration!