Nex Flow™ offers solutions for blow off and cooling but it can be confusing as to which product is best to use.

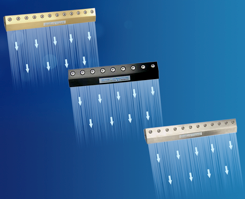

For blowing off or cooling relatively flat or curved surfaces the choice is typically between the Air Blade™ Air Knife or the Air Edger™ Flat Jet. The X-Stream™ Air Blade™ Air Knives are the most efficient as to force/unit air consumption as compared to the standard versions and come in anodised aluminium, hard anodised aluminium and stainless steel. Sizes from 2” to 54”.

The Air Edger™ has the ability to produce much stronger force than the air knives by nature of its design. The Air Edger™ Flat Jet can be banked together on manifolds to produce an air knife effect over long lengths.

The Air Edger™ Flat Jet is available in 2” size in both cast zinc and in 316L Stainless Steel.

5 CONSIDERATIONS FOR CHOICE

1. Cooling or Blow off – The Air Blade™ air knives actually produce a better air flow amplification due to its design than the Air Edger™ and is the better choice if the goal is cooling. The Air Blade™ air knives are designed with smaller gaps starting a .002” (0.05 mm) and can go up to 4 times that (.008” or 0.20 mm) to increase force. However, as you increase the length of the air knives, because the inside plenum remains the same design, the actual overall force produced diminishes with increased length. If increased force is required one option is to use several smaller air knives end to end. The Air Edger™ is designed with gaps starting at .004” (0.10 mm) and can go up to 6 times that (.024” or 0.6 mm) and therefore are ideal for applications where a high force is required and applications against faster moving targets and if you cannot get close to the target. The Air Edger™ has a slightly higher force/unit air consumption (SCFM or SLPM) at their size range and with the flexibility of utilising more shims for a higher gap is the best choice where high force is required.

2. Even Flow – Some applications require a consistent and even long length of even flow making the Air Blade™ air knife the obvious choice.

3. Materials - The Air Blade™ air knives come in three versions: Regular Anodised aluminium, Hard Anodised Aluminium for more difficult environments (especially in areas where sticky oil mist or other material can deposit on the air knife as the Hard Anodised versions are more resistant to such deposits), and 303/304 stainless steel for corrosive and high temperature applications. 316L can be produced on special order. The Air Edger™ comes in either cast zinc or 316L stainless steel.

4. Application Damage Potential – If the application is such that there is a risk of the blow-off or cooling product being damaged, the cost of each piece in the system needs to be considered. For example if you have a 30” Air Blade™ air knife that risks damage due to the process it is used in, it would be more costly to replace one unit than if you have 15 Air Edger™ pieces where maybe only one or two pieces can get damaged.

5. Cost – Given any specific application where both products would work, then cost should be a factor in choice – one long Air Blade™ air knife verses several Air Edger™ pieces on a manifold.

For more information please watch the video demonstration below

To purchase either of these please visit our Air Control & Anti Static page.